Selection Standard for ATEX Explosion-Proof Air Conditioners

1. Environmental Assessment of Application Sites

1.1 Classification of Explosive Hazardous Areas: Gain a detailed understanding of the explosive hazardous area level of the application site, such as Zone 0, Zone 1, and Zone 2.

Zone 0: An environment where explosive gas mixtures are continuously or long-term present.

Zone 1: An environment where explosive gas mixtures may occur during normal operation.

Zone 2: An environment where explosive gas mixtures are unlikely to occur during normal operation; if they do occur, they only exist for a short time.

It’s necessary to select explosion-proof air conditioners with corresponding explosion-proof levels based on the area level to ensure compliance with safety requirements.

1.2 Characteristics of Gases or Dusts

Clarify the type, concentration, ignition temperature, and other characteristics of explosive gases or dusts present in the site. Different gases and dusts have different explosion limits and risk levels.

For example, hydrogen has a wide explosion limit range and high risk. Based on these characteristics, select air conditioners with corresponding explosion-proof performance to prevent explosion accidents during operation.

2. Requirements for Air Conditioner Performance Parameters

2.1 Cooling Capacity

Accurately calculate the required cooling capacity based on factors such as the area of the application site, number of personnel, and heat release from equipment. Generally, industrial sites have large areas and high heat release from equipment, so air conditioners with large cooling capacity should be selected. The calculation can be done using the formula: Cooling Capacity = Room Area × Cooling Capacity Requirement per Unit Area. Determine the appropriate cooling capacity according to actual needs. For example, the cooling capacity and air volume of ATEX Welltech explosion-proof air conditioners are 8500 (units) and 1500 m³/h respectively.

2.2 Energy Efficiency Ratio (EER)

Select explosion-proof air conditioners with high EER to reduce energy consumption and operating costs. EER is the ratio of cooling capacity to cooling power consumption. A higher EER indicates that the air conditioner consumes less electricity for the same cooling capacity.

2.3 Air Volume

Appropriate air volume ensures uniform distribution of indoor air and good comfort. Select air conditioners with appropriate air volume based on the space size and layout of the site. Generally, the air volume can be matched according to the cooling capacity of the air conditioner. Ensure that the air supply of the air conditioner can cover the entire application area to avoid local overheating or overcooling.

3. Explosion-Proof Technical Requirements

3.1 Explosion-Proof Structure

Explosion-proof air conditioners should adopt explosion-proof structures that comply with national standards, such as Flameproof Type, Increased Safety Type, and Intrinsically Safe Type.

(1) The flameproof structure (also the explosion-proof type of ATEX Welltech explosion-proof air conditioners) uses a shell with sufficient strength to isolate components that may generate sparks, electric arcs, and dangerous temperatures from the surrounding explosive gas mixture. It can withstand the explosion of the explosive mixture entering the shell without damage and prevent the combustion or explosion of the explosive mixture outside the shell.

(2) The increased safety structure is applied to equipment that will not generate electric arcs, sparks, or high temperatures that may ignite explosive mixtures under normal operating conditions. Measures are taken to improve its safety level to avoid such phenomena under normal and permitted overload conditions.

(3) The intrinsically safe structure limits the energy of the circuit so that the electric sparks and thermal effects generated under normal and fault conditions cannot ignite the explosive mixture.

3.2 Explosion-Proof Marking

Explosion-proof air conditioners must have clear and permanent explosion-proof markings. Taking the marking in the inspection certificate of ATEX Welltech air conditioners (as shown in the figure below) as an example, this marking is a composite explosion-proof certification mark, covering both gas explosion-proof and dust explosion-proof environments.

3.2.1 First-Line Marking: Ex II 2 G D

"Ex": An internationally universal explosion-proof equipment mark, indicating compliance with explosion-proof standards.

"II": Indicates that the equipment is suitable for explosive environments other than coal mines.

"2": Equipment category, representing "high protection level" (corresponding to "2G/2D" in ATEX).

"G": Suitable for explosive gas environments.

"D": Suitable for explosive dust environments.

3.2.2 Gas Explosion-Proof Part: Ex db ib mb IIC T4 Gb

"db": Flameproof type (d) + Gb (high protection level). It blocks the internal explosion energy through a sturdy shell to prevent ignition of external gases.

"ib": Intrinsically safe type (i) + Gb level. It limits the circuit energy (extremely low voltage/current), so even if electric sparks are generated, they are not enough to ignite gases.

"mb": Encapsulated type (m) + Gb level. It seals components that may generate sparks with materials such as epoxy resin.

"IIC": Gas group, suitable for the most dangerous Group IIC gases (such as hydrogen, acetylene), and can cover Group IIB and Group IIA gases.

"T4": Temperature class, indicating that the maximum surface temperature of the equipment is Class T4 (≤135°C) to avoid igniting gases.

3.2.3 Dust Explosion-Proof Part: Ex ib mb tb IIIC T125°C Db

"ib": Intrinsically safe type (i) + Db level. It limits the circuit energy and is suitable for dust environments with "high protection level" (Db).

"mb": Encapsulated type (m) + Db level. It seals components and is suitable for dust environments with "high protection level" (Db).

"tb": Enclosure protection type (t) + Db level. It prevents dust from entering or accumulating through the enclosure to avoid igniting dust, and is suitable for dust environments with "high protection level" (Db).

"IIIC": Dust group, suitable for the most dangerous Group IIIC dust (such as conductive dust like aluminum powder), and can cover Group IIIB and Group IIIA dust.

"T125°C": Temperature limit for dust environments, indicating that the maximum surface temperature of the equipment is ≤125°C to avoid igniting dust.

ü "Db": Equipment protection level for dust environments, suitable for Zone 21 where dust is frequently present.

3.2.4 Protection Level: IP66

"IP 6": Dust protection level, "dust-tight", completely preventing dust from entering the equipment interior.

"IP 6": Water protection level, capable of withstanding strong water jets (water flow 100 L/min) without harmful effects.

Figure 1: Data Sample from ATEX Welltech Air Conditioner Inspection Certificate

In summary, it is necessary to ensure that the explosion-proof marking matches the explosive hazardous environment of the application site, and the explosion-proof marking should comply with relevant national standards and regulations.

3.3 Explosion-Proof Performance of Electrical Equipment

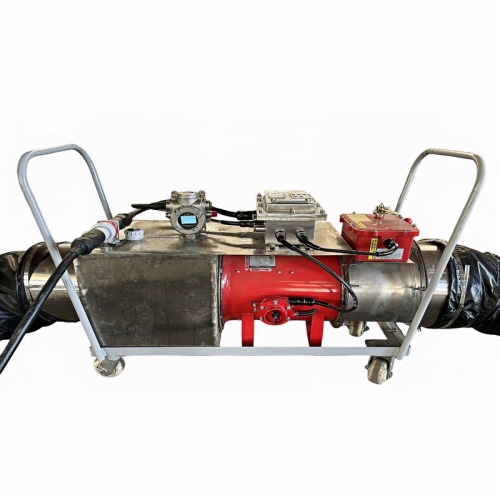

The electrical equipment of ATEX Welltech air conditioners, such as compressors, fans, and controllers, has good explosion-proof performance. Generally, electrical components should be selected to meet explosion-proof requirements, and their insulation performance, voltage resistance performance, etc., should comply with corresponding explosion-proof standards.

4. Reliability and Maintainability

4.1 Brand and Quality

Select explosion-proof air conditioner products from well-known brands with good reputation and production qualifications. Well-known brands usually have advantages in product quality control, R&D investment, and after-sales service, which can ensure the reliability and stability of products. Check whether the product has passed relevant certifications, such as explosion-proof certification and quality management system certification, to ensure that the product complies with national standards and industry requirements.

4.2 Protection Level

The enclosure of the air conditioner should have a high protection level, generally reaching IP54 or above. The IP54 protection level means a dust protection level of Grade 5 (preventing the intrusion of foreign objects, and cannot completely prevent dust intrusion, but the amount of dust intrusion will not affect the normal operation of the equipment) and a water protection level of Grade 4 (preventing the intrusion of splashing water, and preventing water splashing from all directions from intruding into the equipment and causing damage). A higher protection level can effectively protect the internal components of the air conditioner and extend the service life of the equipment.

The ATEX Welltech explosion-proof air conditioners of Shenzhen UniverseTechnology Co., Ltd., as known from the inspection certificate, have a protection level of IP66. This means a dust protection level of Grade 6 and a water protection level of Grade 6, both far exceeding the average level. This is also proof that our explosion-proof air conditioners are of excellent quality and safety.

In summary, the core of selecting industrial explosion-proof air conditioners lies in balancing safety adaptability and practical performance. It is necessary to match the corresponding explosion-proof level, structure, and protection standards based on the explosive hazard characteristics of the application scenario, while considering key parameters such as cooling capacity and energy efficiency. Prioritizing compliant and reliable products ensures safe and stable operation in flammable and explosive environments.