HWSS-336 ATEX System: Safety Configuration for Platform

1. Usage Specifications

It shall be verified whether the necessary resources (scaffolding, power supply, gas supply, etc.) determined through work planning are available at the construction site of the Work Habitat.

The construction of the Work Habitat must be guided and managed by professionals.

The Work Habitat is made of flame-retardant materials, with sufficient rigidity, and its structure shall ensure that the heat and sparks generated during operations do not pose an ignition source risk to the outside.

The Work Habitat is equipped with observation windows to facilitate the Living Habitat Supervisor/Fire Watch to monitor the operation inside the Habitat.

Both the interior of the Work Habitat and the control box are equipped with manual emergency stop buttons. Operators can cut off the power supply of all equipment or external power through the emergency stop button.

The internal structure of the Work Habitat may allow combustible gas ingress; however, if combustible gas enters, compensation measures must be implemented, such as depressurizing and purging the pipelines to eliminate potential sources of hydrocarbons.

Welding and heat treatment equipment must be placed inside the Work Habitat; if necessary, they can be placed in a separate living Habitat.

The structure and fabric strength of the Work Habitat must be able to withstand the relevant wind stress in the area where it is placed. The design of the living Habitat can generally withstand wind speeds of 15 to 20 m/s, and special designs can also be made for harsher environments.

The Work Habitat is equipped with an automatically closing door (the living Habitat may lose overpressure only a few seconds after the Habitat door is opened). A good evacuation route from the Work Habitat to the safe area shall be prioritized in planning and marked with signs. If necessary, a backup evacuation route shall be set up—except for the Work Habitat door, there shall be an additional escape route in the form of kickable or tearable panels.

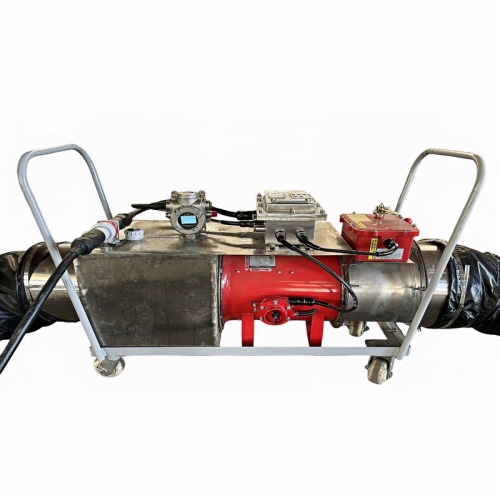

The fan inlet shall be set in a safe area (away from hazardous zones, ideally in the "upwind direction") to ensure sufficient fresh air supply to the living Habitat. If combustible gas is detected, the system will automatically close the fan air damper sand cut off the power and gas supply inside the Work Habitat.

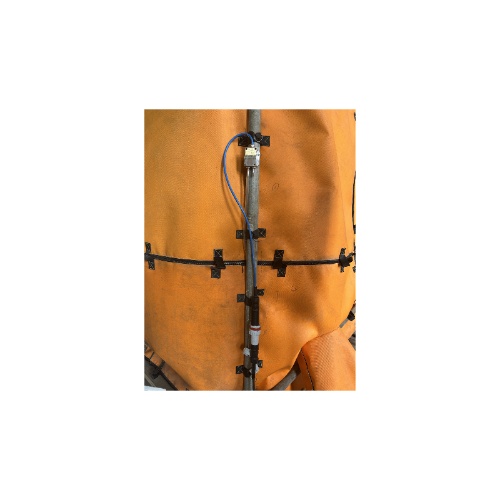

The Work Habitat must be equipped with at least three external gas detectors. If any detector detects gas (concentration exceeding 10% LEL), all equipment inside the Work Habitat shall be automatically isolated (tripped).

When the air pressure inside the Work Habitat fails to meet the requirements, all equipment inside the Habitat shall also be automatically isolated (tripped), or isolated by the living Habitat supervisor/fire supervisor in a simple manner.

The explosion-proof system is equipped with an audible and visual alarm device. In case of system alarm or emergency, the audible and visual alarm will be automatically triggered to prompt personnel to evacuate or take emergency handling measures.

If gas (propane-oxygen/acetylene) is used, the gas cylinders must be placed outside the living Habitat. The gas (propane-oxygen/acetylene) pipelines shall be equipped with solenoid valves, which will automatically cut off the gas supply when any gas detector alarms.

2. Pre-Use Inspection

The Area Supervisor/Area Technician shall conduct a final inspection together with the Work Habitat installer, Health, Safety and Environment (HSE) specialist, and the Construction Team Leader of the construction team to confirm that the construction of the Work Habitat meets the requirements. The inspection record form must be placed in a file folder together with the Permit to Work (PTW) and kept outside the Work Habitat.

Visual inspections shall be conducted daily and during shift changes. The inspection record form must also be placed in the file folder outside the Work Habitat together with documents such as the Permit to Work (PTW).

3. Operation of the Work Habitat

During the use of the Work Habitat, the installer shall be on standby at all times, unless other personnel capable of ensuring the integrity of the Work Habitat are present during this period.

When gas is detected in the device/facility, the electric ignition sources inside the Work Habitat shall be automatically turned off. If the flammable gas or oxygen cylinders are not equipped with solenoid valves for automatic shutdown, the open-flame torches must be extinguished immediately and the gas supply cylinders must be manually isolated when any alarm is triggered.

When using the Work Habitat, a dedicated Work Habitat Supervisor/Fire Duty Officer shall be assigned, whose main responsibility is to monitor the operation site. In case of emergency, press the emergency stop button immediately to stop the operation.